MYCOweave

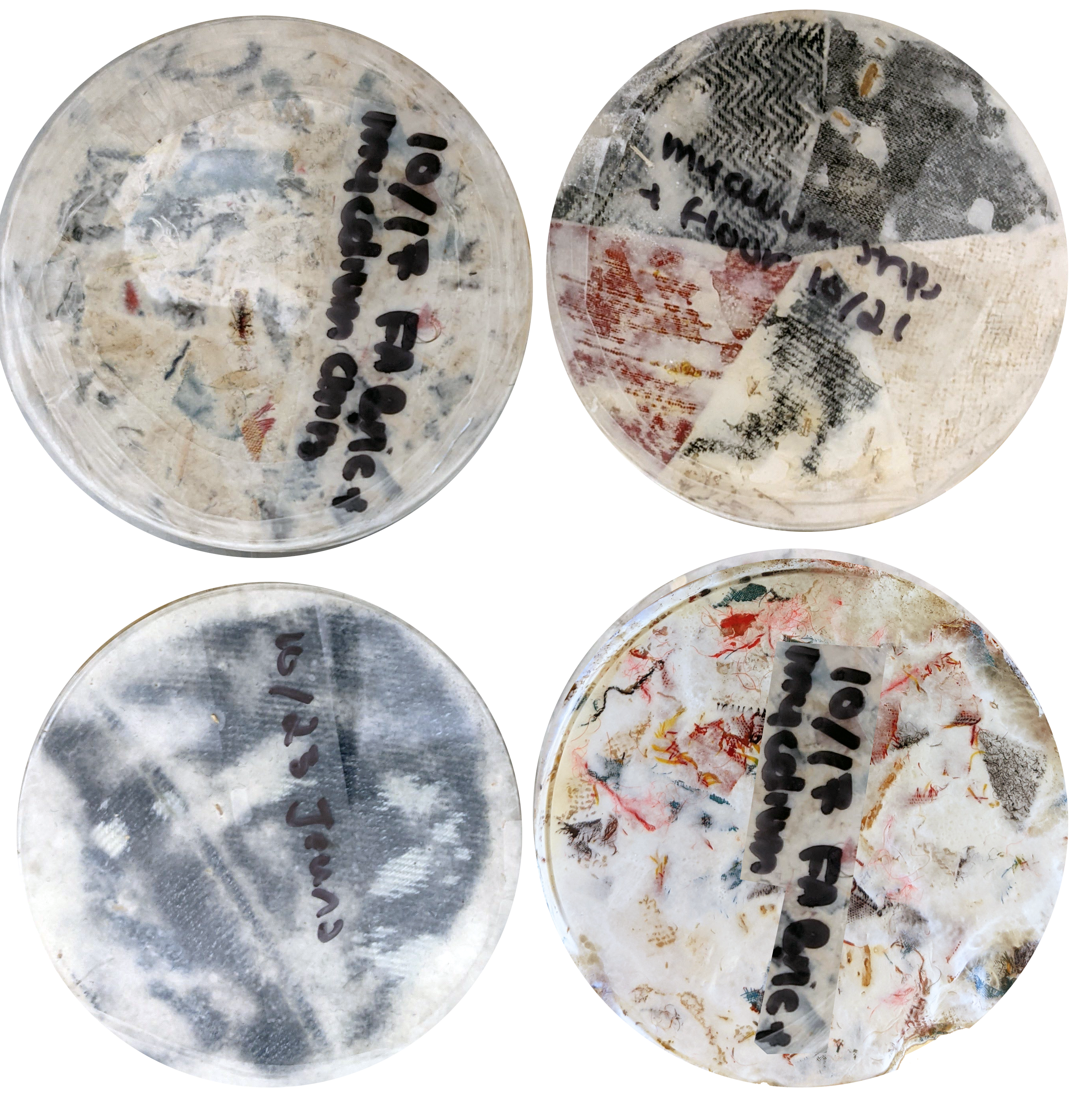

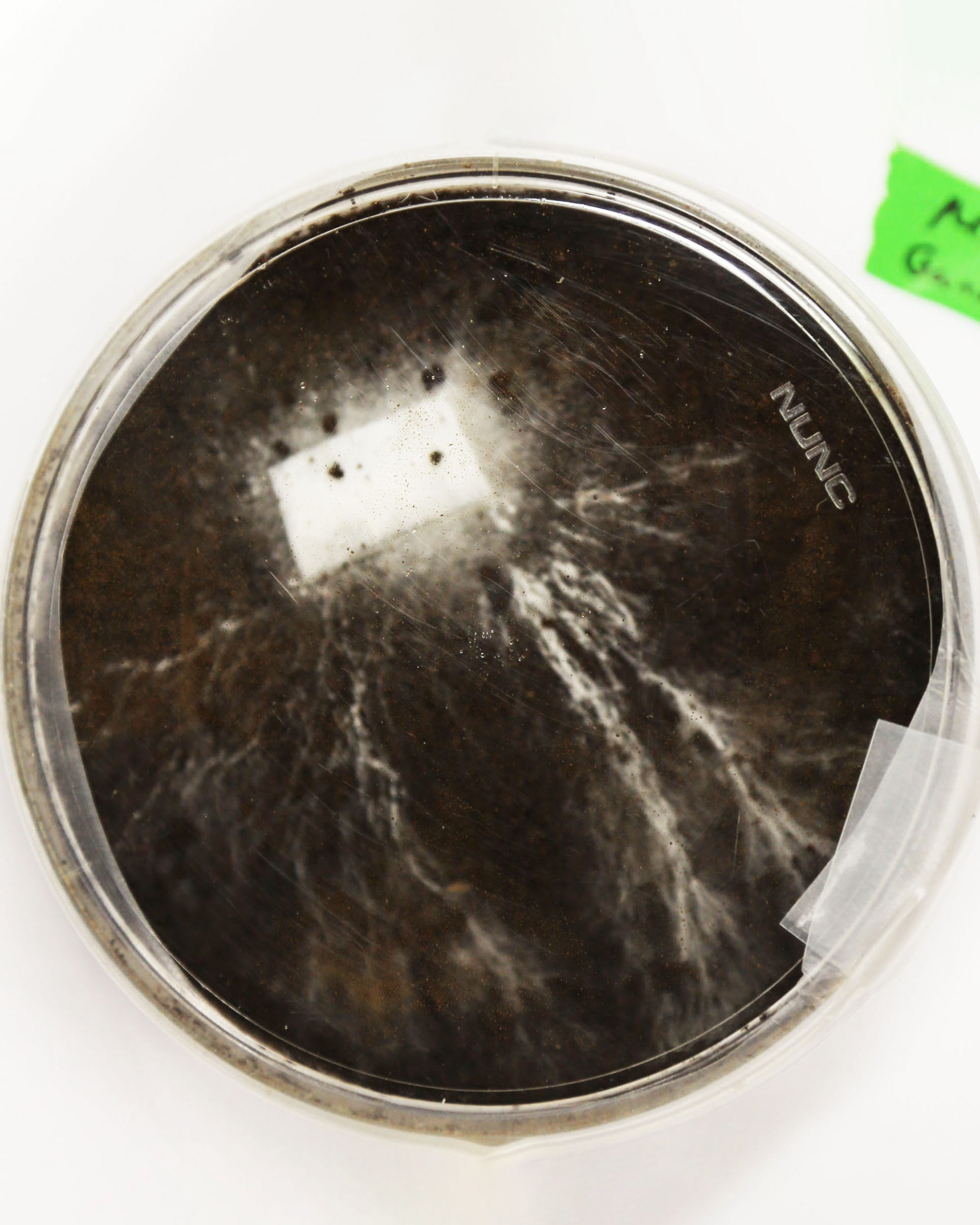

Upclose image of a sample of Mycoweave.

Mycoweave proposes mycelium, the vegetative structure of mushrooms, as one solution to the textile waste generated in the fashion industry by non-recyclable blended fibers. Mycelium has the ability to break down almost any carbon-based material. This means non-recyclable textile waste that has at least one carbon based fiber can be upcycled into a new fabric by having the mycelium consume and bind the scraps together. The end product has a painterly look and leather-like properties. The material can be grown in different shapes and sizes. The process is circular as old material can be consumed by a new batch of mycelium.

--

Longlisted for a 2022 Dezeen Design Award in the wearable and sustainable design categories.

THE CONCEPT

Mycelium growing on coffee grounds.

Mycelium growing on coffee grounds.

Mycelium is the part of the mushroom that is found underground. It forms a network of fungal threads, composed of long tubular cells called hyphae. Mycelium plays a key role in our ecosystems, breaking down organic material into raw material that can be used again.

It is estimated that every second, a garbage truck's worth of clothing is burnt or buried in a landfill. Only 13% of textiles from the apparel industry get recycled. One cause of this low rate of recycling is our current inability to recycle blended textiles. Different types of fibers must be segregated and treated separately and there is currently no commercially available or consistent way to do this mechanically or chemically.

Atacama desert, Chile, which has become a destination for garment disposal for the fast fashion industry. Photographed by Argentine journalist Jason Mayne.

Atacama desert, Chile, which has become a destination for garment disposal for the fast fashion industry. Photographed by Argentine journalist Jason Mayne.

At the same time, many of the fibers in blended fabrics, such as wool and cotton, are proteins and carbohydrates that contain carbon as a core component. Because mycelium, the vegetative structure of the mushroom, can break down almost any carbon-based material, I believe that a mycelium-based process can be a solution to this blended-textile waste.

In this proposed process, old garments and waste fabric scraps, particularly those composed of blended fibers, are upcycled into a new fabric (Mycoweave) by having the mycelium consume and bind the scraps together.

THE PROCESS

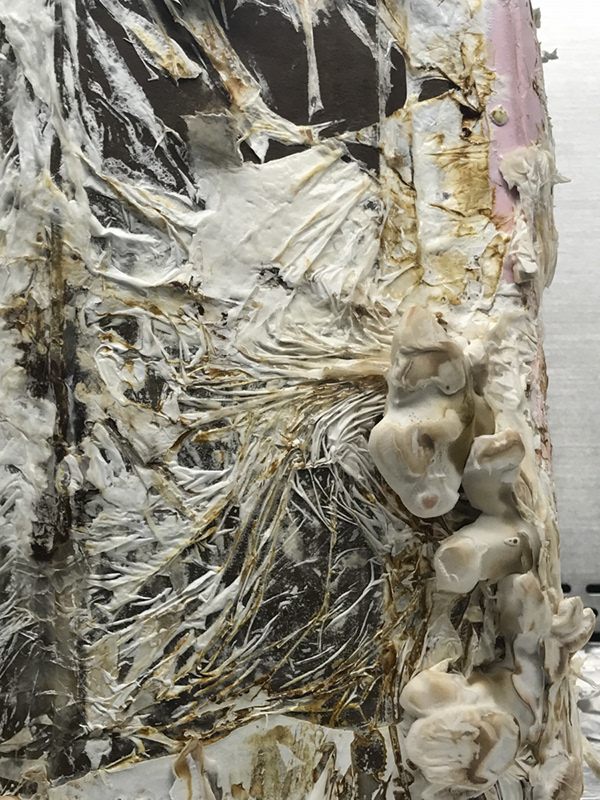

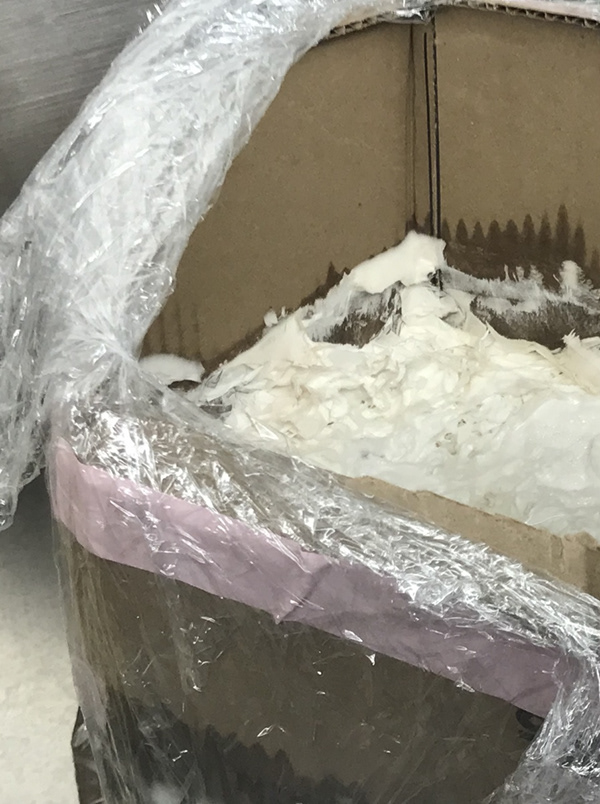

Mycoweave is created by first sterilizing the fabric scraps and then inoculating them with mycelium. The inoculated fabrics are then placed in a mold and left to grow for 2-3 weeks.

After 2-3 weeks of growth, the mycelium fabric is removed from the mold. The new Mycoweave material is processed by pressing the material and allowing it to dry, which halts the growth of the mycelium.

Once dried, the material is plasticized with glycerol (vegetable oil) and cooked in order to kill the mycelium. The end product has a supple, leather-like quality.

While the material is leather-like in regards to its feel and drape, Mycoweave is a unique material with interesting properties of its own. The colors and textures of the original fibers consumed are preserved to varying degrees, depending on how long the mycelium is grown, giving Mycoweave a unique painterly appearance.

Upclose images of varations of Mycoweave.

In addition, unlike traditional leather, the fabric can be grown in different shapes and sizes, opening up the possibility of growing the fabric into a garment pattern or even in a three-dimensional form. Thus, in addition to offering a solution to textile waste, Mycoweave opens up new design, aesthtic, and construction possibilities.

The process of creating Mycoweave is circular because old Mycoweave can be upcycled by feeding it to a new batch of mycelium.

MYCO for Mars

Summer 2018 synthetic biology intern project at NASA Ames.

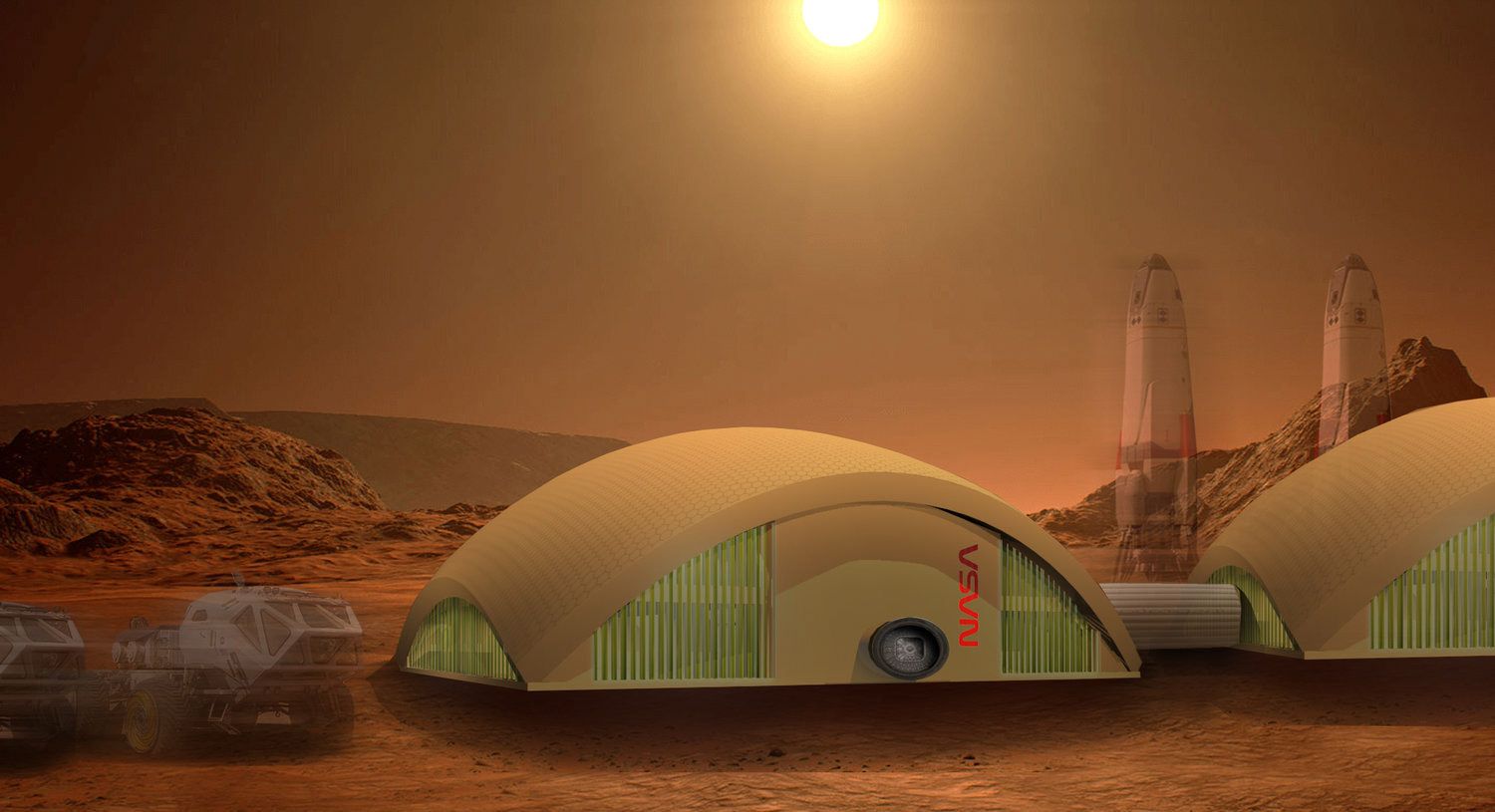

Rendering of proposed habitat by our collaborator, redhouse studio

“Science fiction often imagines our future on Mars and other planets as run by machines, with metallic cities and flying cars rising above dunes of red sand...But the reality may be even stranger.”

- NASA to Popular Mechanics on its MYCO-Architecture Program

During the Summer of 2018, I conducted synthetic biology research at the NASA Ames Research Center with Professor Rothschild as a part of the Stanford-Brown-RISD iGEM Team.

Our research, detailed below, was on the development of affordable, light-weight, and sustainable human habitats for Mars and the Moon through the use of fungal mycelium. My areas of focus were the development of the mycelium based material, mission architecture, and potential applications on Earth.

We presented our work at the 2018 NASA Innovative Advanced Concepts (NIAC) Symposium and the 2018 international genetically engineered machine (iGEM) competition.

At the competition, the project was nominated for best new composite part and best manufacturing project. To support my research I was awarded the Rhode Island Space Grant and Brown Undergraduate Teaching and Research Award (UTRA).

How will humans live on Mars?

Mars Ice Habitats by Space Exploration Architecture and Clouds Architecture Office of New York for NASA’s 3D-Printed Habitat Challenge

Mars Ice Habitats by Space Exploration Architecture and Clouds Architecture Office of New York for NASA’s 3D-Printed Habitat Challenge

The human exploration of Mars has been one of NASA's goals for years--with proposed expeditions within the next decade. However, there is a fundamental question that needs to be answered first: how will humans live on Mars?

A visit to Mars could last months to years. Therefore, the habitat must be able to maintain the long-term physical and mental well-being of the astronauts and survive the extreme environment of Mars

Perliminary Research

To answer some of our primary questions about what the design of a human mission to Mars we interviewed Dr. Michael Meyer, the lead scientist of NASA’s Mars Exploration Program, Dr. Lisa Pratt, NASA’s planetary protection officer, and Amy Kronenberg, Biophysicist Staff Scientist at the U.S. Department of Energy Lawrence Berkeley Labs and member of the NASA Innovative Advanced Concepts advisory board.

Team Members Emilia Mann, Leo Penny, and Javier Syquia meeting with Dr.Michael Meyer

Team Members Emilia Mann, Leo Penny, and Javier Syquia meeting with Dr.Michael Meyer

The Project Proposal

Transportation of material through space is a basic yet fundamental component of many of NASA’s objectives.

Whether this material is equipment needed to test for life on Mars or the structures that allow for prolonged habitation, it must travel from earth to its celestial destination, thus incurring great economic and energy costs.

But, what if it didn’t have to be transported from earth? What if it could be grown on planet?

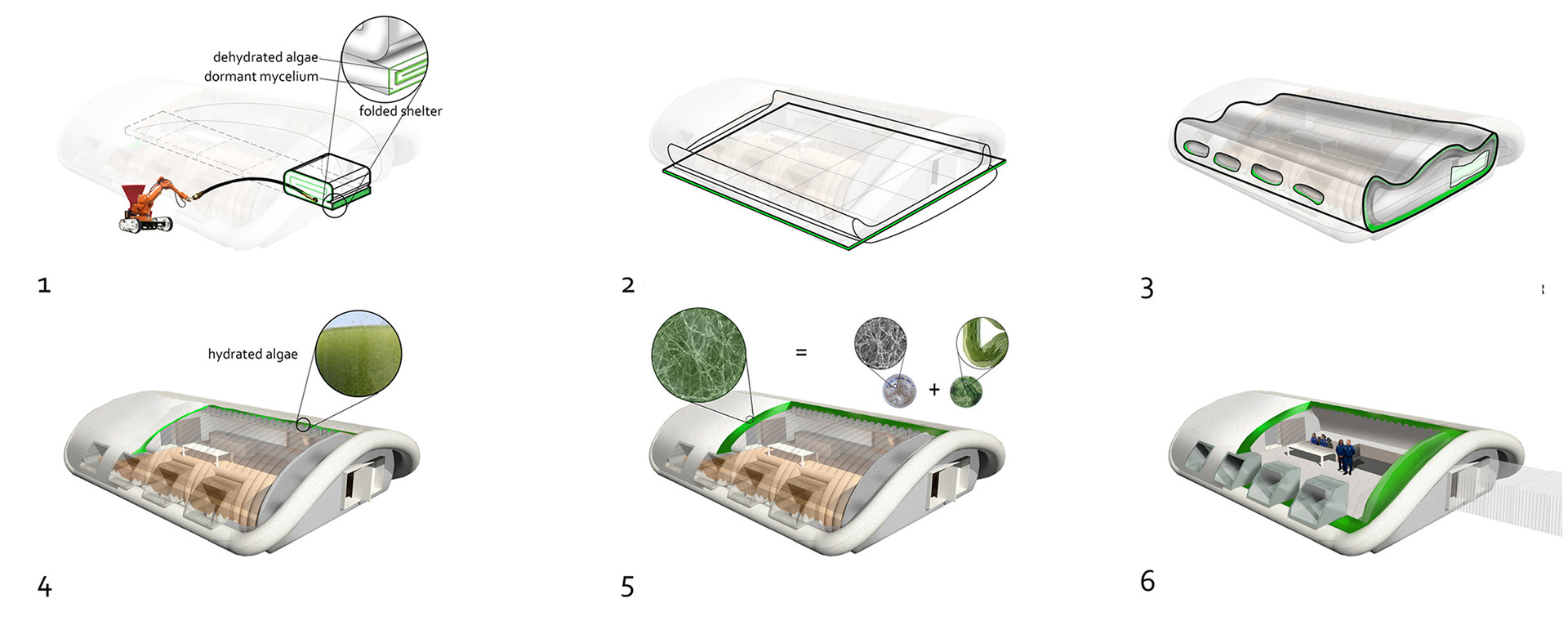

Based on this concept, our team proposed we explore the use of fungal mycelium as a light-weight, durable material that could be grown on site using spores to create habitats and other necessary items.

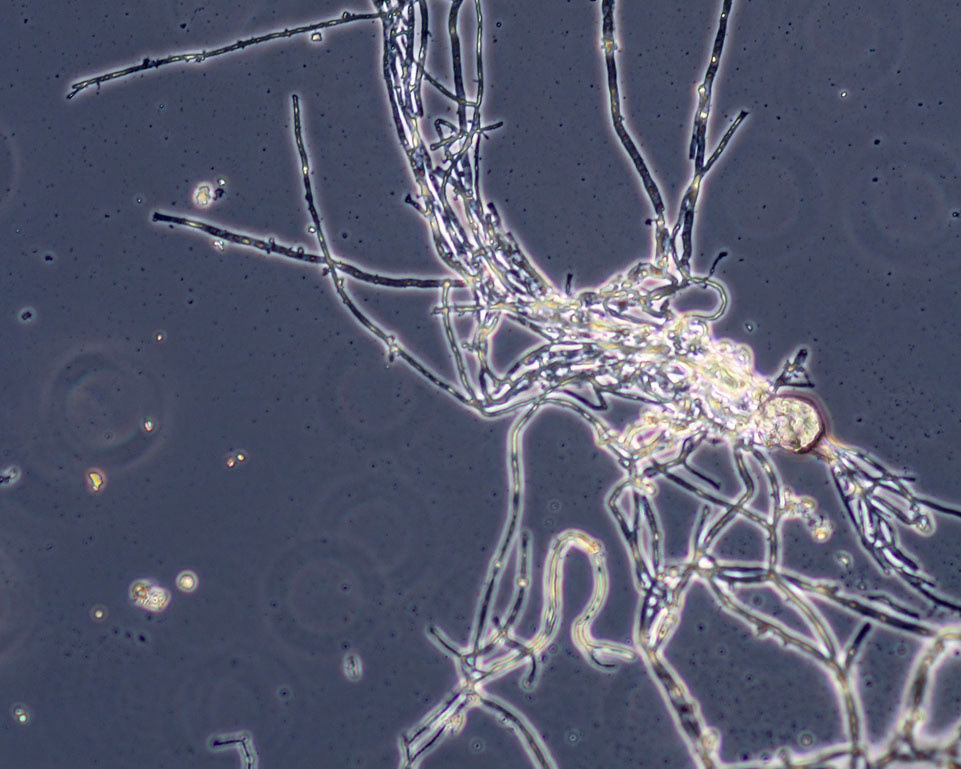

Microscopic image of G. lucidum mycelium, taken by team member Leo Penny and advisor Lynn Rothschild.

Microscopic image of G. lucidum mycelium, taken by team member Leo Penny and advisor Lynn Rothschild.

Mycelium is the vegetative structure of a fungus and is analogous to the root system of most plants. As it seeks out nutrients in a substrate it branches out, filling in the gaps of the material.

We initially gravitated towards using mycelium as the core material in the design of our habitat for Mars and the Moon because of its self-perpetuating property--given a substrate it can grow into the shape of any mold it is placed in.

The outer layer would hold water sourced from subsurface ice water at our landing site. The function of this layer is to provide temperature insulation and radiation protection.

The middle layer would hold the substrate the mycelium would bind to.

The inner layer is designed to hold the mycelium, which provides the structural integrity and additional radiation protection for the habitat.To demonstrate the potential for using mycelium to grow materials and structures both on and off planet, we tested the growth of mycelium on a variety of different substrates.

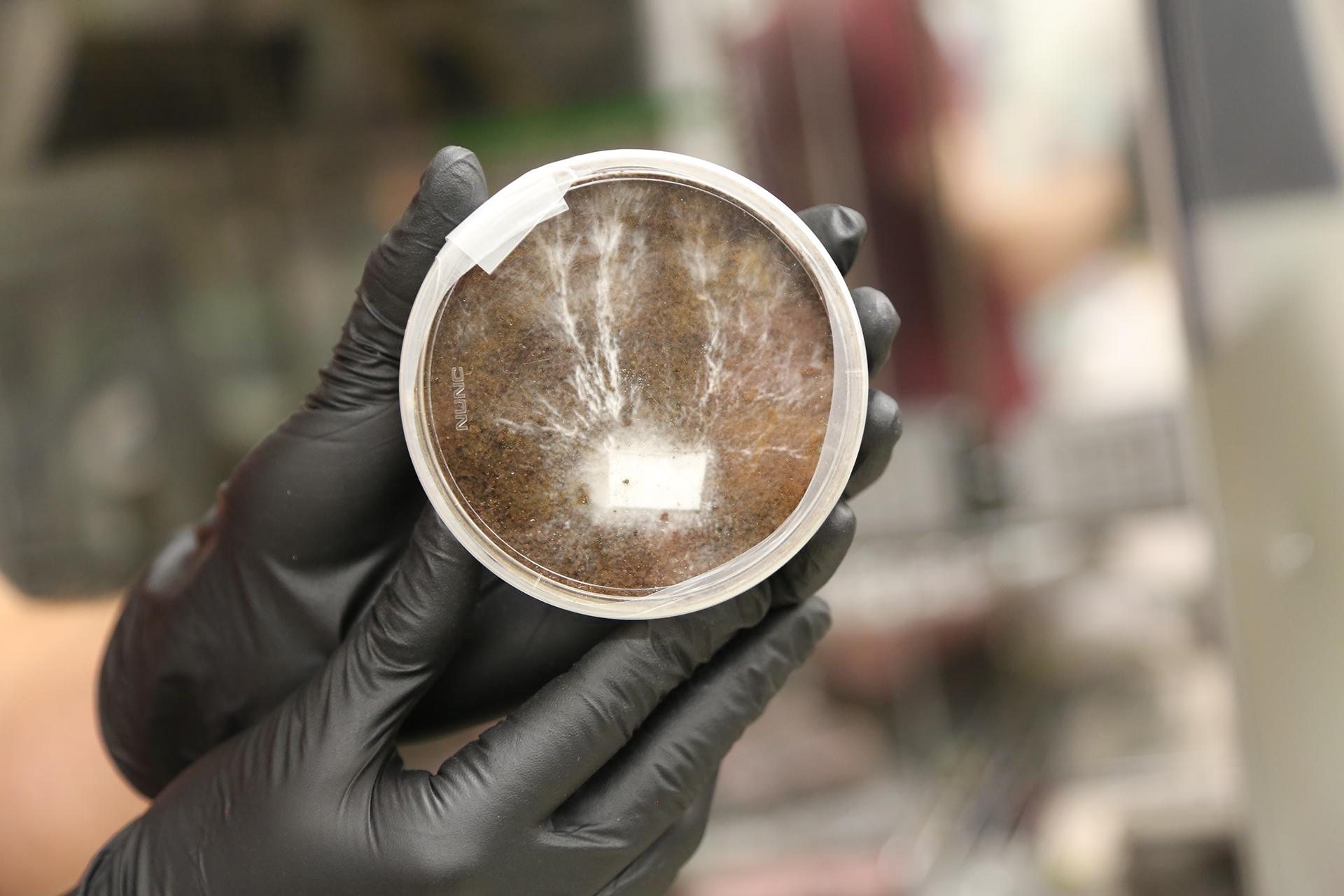

The mycelium successfully grew on Martian and Lunar regolith stimulant with minimal nutrients added in the form of PDY (Potato-Dextrose-Yeast) solution. Other noteworthy substrates with exceptional material and environmental promise for terrestrial applications are yard waste, sawdust, used ground coffee beans, and other forms of food waste.

Mycelium growing on Martian regolith and PDY

![]()

Mycelium growing on Lunar regolith and PDY Mycelium growing on quinoa flakes

![]() Mycelium growing on quinoa flakes

Mycelium growing on quinoa flakes

Mycelium growing on Lunar regolith and PDY Mycelium growing on quinoa flakes

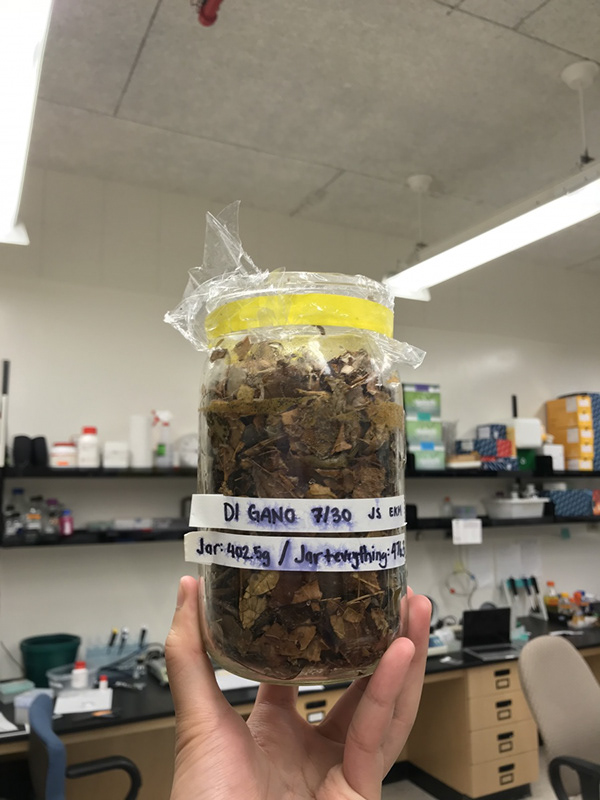

Mycelium grown on used coffee grounds.

Mycelium grown on used coffee grounds.Structural Development

Mycelium spores growing on woodchips

Pile of bricks produced with mycelium and yard waste, wood chips

Pile of bricks produced with mycelium and yard waste, wood chips

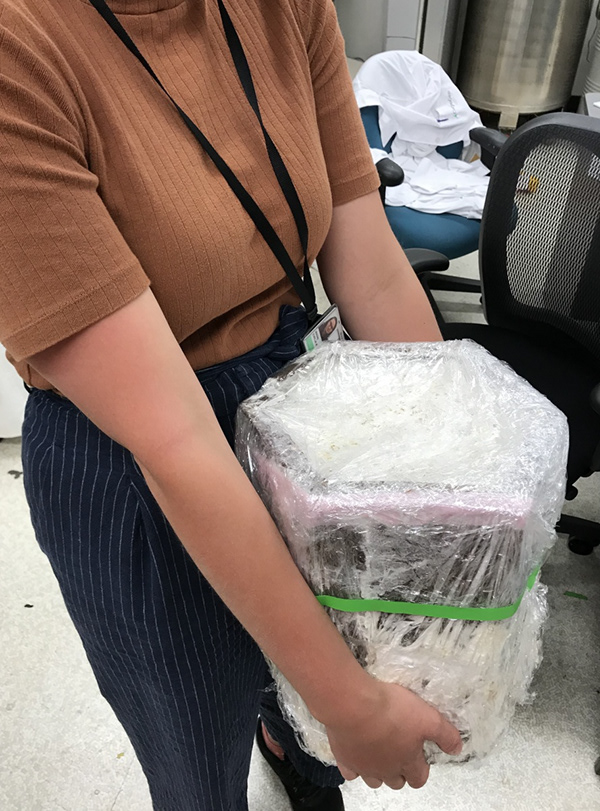

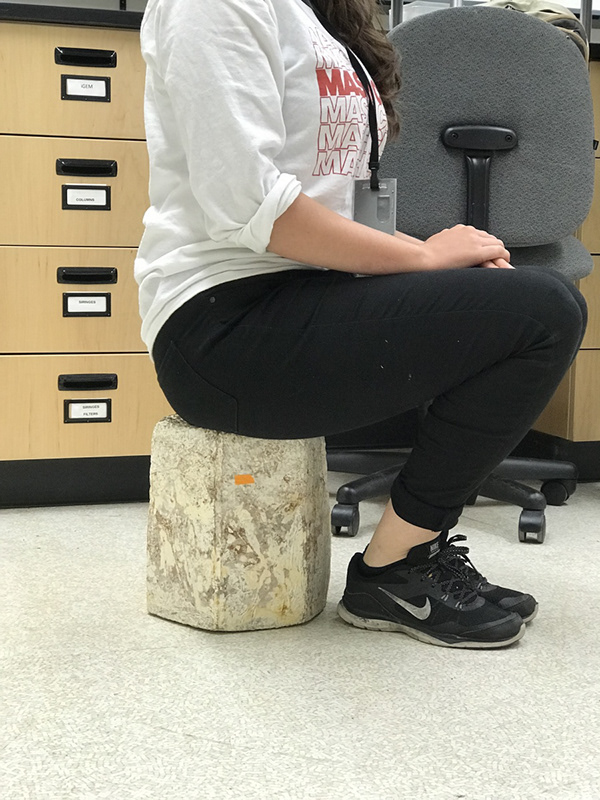

Process of growing Mycelium based stool with yardwaste as the substrate

As our research progressed and we spoke to more experts working with mycelium, such as Phil Ross (founder of MycoWorks) and Eben Bayer ( one of the co-founders of Ecovative), it became clear to us that mycelium has the potential to revolutionize product manufacturing on earth by introducing a completely biodegradable material that is also self-growing. Applications on Earth

These key characteristics will allow manufactures to cut back on the cost, time, energy, and environmental impact involved with traditional production methods. And the ability of manipulate the mechanical properties of the materials ensures that mycelium could be used as a substitute for a variety of products--from furniture to clothing to medical devices.

In response to this exciting realization we began exploring the ways mycelium could be used to create other products that might be necessary for our habitat--ranging from furniture, to scientific instruments, to a filtration system, to even a Rover chassis. We even generated some designs and prototypes for a few of these ideas, fully flushing out the idea of an entire living space created from one material.

For a more detailed report on our project please visit our website by clicking the button below.

Lamps by Ecovative

Diagram by our collaborator,

Diagram by our collaborator,