MYCOweave

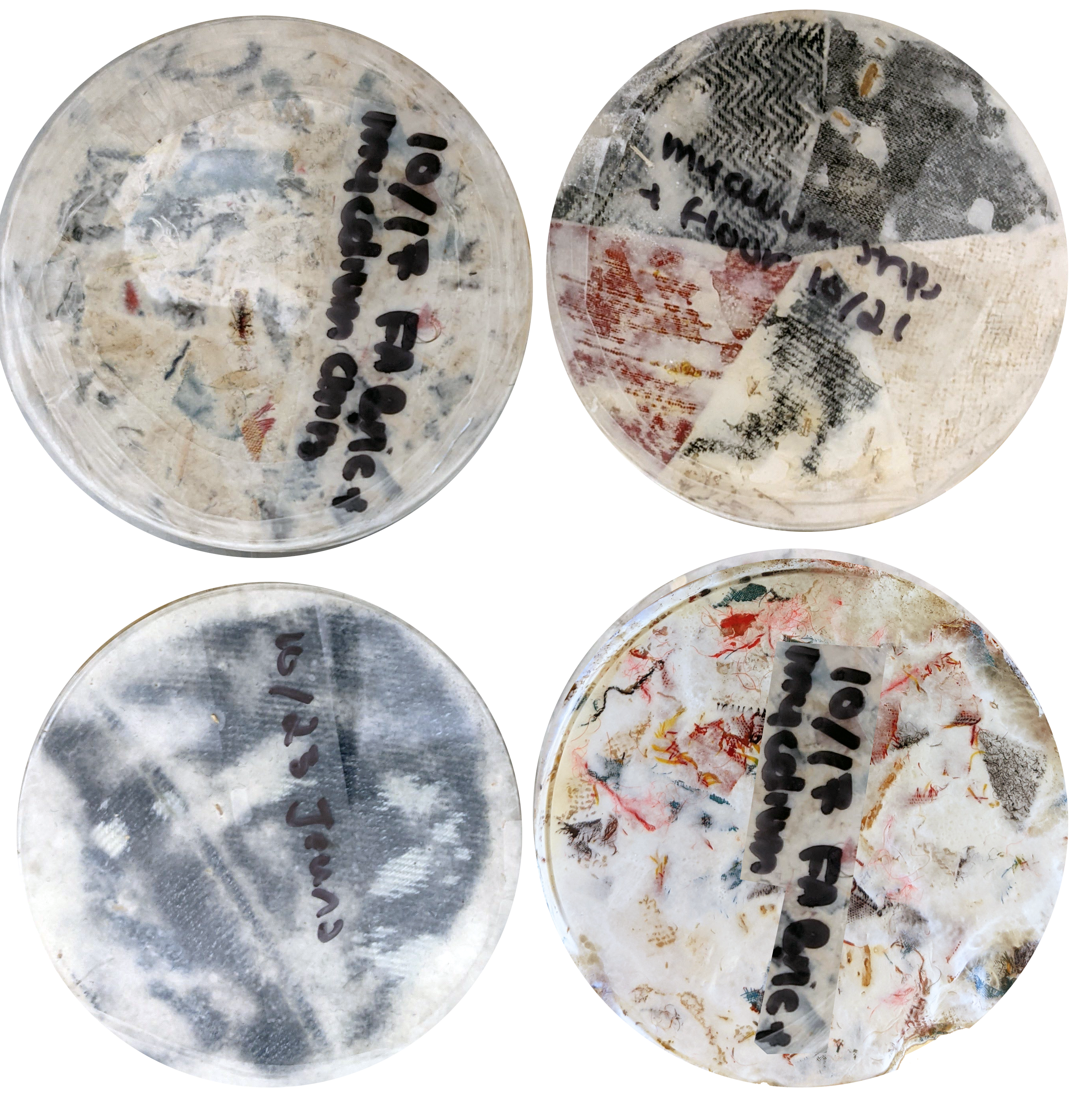

Upclose image of a sample of Mycoweave.

Mycoweave proposes mycelium, the vegetative structure of mushrooms, as one solution to the textile waste generated in the fashion industry by non-recyclable blended fibers. Mycelium has the ability to break down almost any carbon-based material. This means non-recyclable textile waste that has at least one carbon based fiber can be upcycled into a new fabric by having the mycelium consume and bind the scraps together. The end product has a painterly look and leather-like properties. The material can be grown in different shapes and sizes. The process is circular as old material can be consumed by a new batch of mycelium.

--

Longlisted for a 2022 Dezeen Design Award in the wearable and sustainable design categories.

THE CONCEPT

Mycelium growing on coffee grounds.

Mycelium growing on coffee grounds.

Mycelium is the part of the mushroom that is found underground. It forms a network of fungal threads, composed of long tubular cells called hyphae. Mycelium plays a key role in our ecosystems, breaking down organic material into raw material that can be used again.

It is estimated that every second, a garbage truck's worth of clothing is burnt or buried in a landfill. Only 13% of textiles from the apparel industry get recycled. One cause of this low rate of recycling is our current inability to recycle blended textiles. Different types of fibers must be segregated and treated separately and there is currently no commercially available or consistent way to do this mechanically or chemically.

Atacama desert, Chile, which has become a destination for garment disposal for the fast fashion industry. Photographed by Argentine journalist Jason Mayne.

Atacama desert, Chile, which has become a destination for garment disposal for the fast fashion industry. Photographed by Argentine journalist Jason Mayne.

At the same time, many of the fibers in blended fabrics, such as wool and cotton, are proteins and carbohydrates that contain carbon as a core component. Because mycelium, the vegetative structure of the mushroom, can break down almost any carbon-based material, I believe that a mycelium-based process can be a solution to this blended-textile waste.

In this proposed process, old garments and waste fabric scraps, particularly those composed of blended fibers, are upcycled into a new fabric (Mycoweave) by having the mycelium consume and bind the scraps together.

THE PROCESS

Mycoweave is created by first sterilizing the fabric scraps and then inoculating them with mycelium. The inoculated fabrics are then placed in a mold and left to grow for 2-3 weeks.

After 2-3 weeks of growth, the mycelium fabric is removed from the mold. The new Mycoweave material is processed by pressing the material and allowing it to dry, which halts the growth of the mycelium.

Once dried, the material is plasticized with glycerol (vegetable oil) and cooked in order to kill the mycelium. The end product has a supple, leather-like quality.

While the material is leather-like in regards to its feel and drape, Mycoweave is a unique material with interesting properties of its own. The colors and textures of the original fibers consumed are preserved to varying degrees, depending on how long the mycelium is grown, giving Mycoweave a unique painterly appearance.

Upclose images of varations of Mycoweave.

In addition, unlike traditional leather, the fabric can be grown in different shapes and sizes, opening up the possibility of growing the fabric into a garment pattern or even in a three-dimensional form. Thus, in addition to offering a solution to textile waste, Mycoweave opens up new design, aesthtic, and construction possibilities.

The process of creating Mycoweave is circular because old Mycoweave can be upcycled by feeding it to a new batch of mycelium.